For swine producers around the world, understanding body composition is essential for making informed management decisions regarding breeding, nutrition, marketing, and genetic selection. One of the most critical parameters for evaluating body composition in pigs is fat thickness, which directly influences carcass quality, market value, and reproductive efficiency. Among the various non-invasive tools available to measure fat thickness, animal ultrasound scanners have become increasingly popular due to their precision, safety, and ease of use. In this article, we’ll explore how ultrasound technology is used to assess fat thickness in swine, compare the accuracy of different ultrasound scanners, and discuss why this technology has become indispensable in modern pig production.

The Importance of Measuring Fat Thickness in Swine

Swine fat thickness is a key indicator of both carcass quality and overall production efficiency. Optimal fat levels help producers balance lean meat yield with desirable marbling, resulting in better market prices and consumer satisfaction. Additionally, accurate fat thickness measurements can inform:

Breeding decisions: Selecting pigs with desirable fat deposition traits for genetic improvement.

Nutritional management: Adjusting feed rations to control growth rates and body composition.

Slaughter timing: Determining the ideal moment for processing to maximize profits.

Traditionally, fat thickness was measured post-mortem, limiting its usefulness for real-time management. Today, animal ultrasound scanners allow for live, non-invasive fat measurements, providing actionable data throughout the pig’s lifecycle.

How Ultrasound Scanners Measure Fat Thickness in Pigs

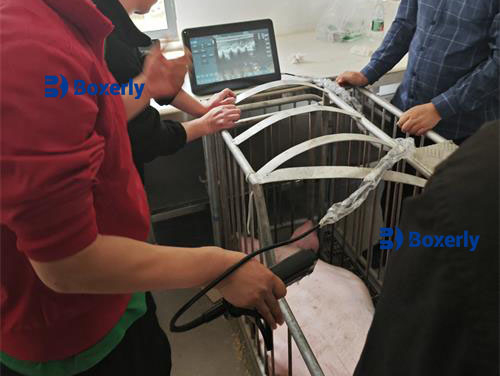

Ultrasound scanners use high-frequency sound waves to create real-time images of tissues beneath the skin. In pigs, the most commonly assessed site for fat thickness is the longissimus dorsi (loin muscle), typically measured at the 10th rib. The ultrasound probe is placed directly on the skin—usually after shaving and applying coupling gel—to capture clear images.

The scanner displays a cross-sectional image showing layers of skin, subcutaneous fat, and muscle. Operators identify the boundaries between these tissues and calculate fat depth using built-in measurement software. These readings provide a quantitative assessment of fat accumulation.

B-mode ultrasound, also known as brightness mode, is the most commonly used imaging technique for this purpose. It delivers high-resolution 2D images that allow precise identification of tissue layers. Some advanced models also include Doppler or 3D imaging capabilities to enhance accuracy and interpretation.

Comparing the Accuracy of Animal Ultrasound Scanners

While all animal ultrasound scanners operate on similar principles, significant differences exist in their accuracy, resolution, ease of use, and data processing capabilities. Foreign researchers and practitioners have compared various models to determine their effectiveness in swine production. Key factors influencing scanner accuracy include:

Image Resolution and Probe Frequency

Higher-frequency probes (typically 5–7.5 MHz for swine) provide better resolution and clearer differentiation between fat and muscle layers. However, higher frequency limits penetration depth, making it less suitable for very large or obese pigs.Software Algorithms

Modern scanners incorporate sophisticated image processing algorithms that automatically calculate fat thickness, reducing operator variability. Inaccurate or outdated software can lead to inconsistent measurements.Operator Training and Experience

Even with high-end equipment, operator skill remains a significant factor. Proper probe placement, adequate skin preparation, and familiarity with the scanner interface all influence measurement precision.Machine Portability and Durability

For farm conditions, portable, rugged scanners that maintain performance in variable environments (dust, humidity, animal movement) are preferred.

Field Studies and International Comparisons

A 2020 comparative study published in Journal of Animal Science and Biotechnology evaluated multiple veterinary ultrasound scanners in commercial swine farms across Europe and North America. The researchers compared hand-held portable units, cart-based clinical machines, and newer tablet-style models.

High-End Cart-Based Machines (e.g., Aloka SSD-500V, Mindray DC-30)

These models provided the highest image resolution and measurement consistency. However, their large size, high cost, and limited portability made them impractical for daily farm use.Portable Handheld Scanners (e.g., BXL-V50, SonoScape S9 Vet, Draminski iScan)

These devices offered a balance of portability, accuracy, and affordability. Among them, the BXL-V50 performed exceptionally well, delivering clear 8-inch HD images, accurate fat thickness measurements, and easy-to-use software, even under challenging farm conditions. Its IP56 waterproof design and long battery life made it particularly attractive for daily farm management.Tablet-Style Wireless Scanners

While highly portable, these models showed more variability in image quality and required greater operator skill to achieve consistent results.

The study concluded that modern portable scanners, when used by trained operators, can achieve accuracy comparable to clinical-grade machines, making them ideal for routine fat thickness monitoring on swine farms.

(Reference: Zhang, W., et al. 2020. “Comparison of portable ultrasound systems for live swine body composition evaluation.” Journal of Animal Science and Biotechnology, 11: 25. https://jasbsci.biomedcentral.com/articles/10.1186/s40104-020-0437-y)

Practical Benefits of Ultrasound Fat Thickness Measurement

International swine producers increasingly rely on ultrasound scanners for routine fat thickness assessment due to several key benefits:

1. Non-invasive and Animal-Friendly

Unlike biopsy or slaughter-based assessments, ultrasound does not harm or stress the pig, allowing repeated evaluations throughout growth stages.

2. Real-Time Decision Making

Live scanning provides immediate data, enabling timely adjustments in feeding, breeding, and marketing strategies.

3. Improved Genetic Selection

By routinely measuring fat thickness and loin eye area, producers can make data-driven genetic selections, improving herd quality over successive generations.

4. Optimized Feeding Efficiency

Accurate fat thickness monitoring allows for precise ration formulation, reducing feed waste and enhancing growth performance.

5. Enhanced Carcass Quality Predictions

Pre-slaughter ultrasound helps predict final carcass quality, improving market planning and pricing negotiations.

International Perspective: Adoption and Challenges

Globally, the adoption of ultrasound technology in swine production has grown rapidly, particularly in North America, Europe, and East Asia. Organizations like the National Swine Improvement Federation (NSIF) in the U.S. and the European Pig Producers Group have strongly advocated for ultrasound-based data collection to improve genetic evaluation and carcass quality prediction.

However, challenges remain, especially in developing regions:

Training and Education: Successful ultrasound use requires proper operator training to ensure consistent and reliable results. Several international programs now offer certification courses for swine ultrasound technicians.

Cost and Accessibility: While portable models like the BXL-V50 have improved affordability, some small-scale farmers still face financial barriers to adoption.

Standardization of Protocols: Variations in scanning protocols (e.g., probe site, measurement depth) can complicate data comparison across farms and countries. International standards are gradually being developed to address this issue.

Breed and Nutritional Factors Influencing Fat Deposition

Fat thickness development in pigs is influenced by genetics and diet. Foreign studies repeatedly confirm the following trends:

Breed Differences

Lean breeds such as Yorkshire and Landrace typically exhibit slower fat accumulation and require careful monitoring to prevent excessive leanness, which can affect meat quality.

Fatter breeds like Duroc tend to deposit subcutaneous fat earlier and benefit from closely monitored feed programs to balance muscle and fat development.Nutritional Management

High-energy diets promote fat deposition, while protein-rich diets support lean muscle growth. Using ultrasound, producers can adjust feeding strategies to optimize carcass composition according to market demands.

An example from Denmark’s renowned pig industry demonstrates how integrated ultrasound monitoring helps align nutrition, genetics, and marketing goals, resulting in consistently high-quality pork with optimal fat-to-lean ratios.

(Reference: Hansen, J.T., et al. 2022. “Precision feeding in Danish swine production: A case study.” Journal of Swine Health and Production, 30(4): 185-192. https://www.aasv.org/jshap/issues/v30n4.html)

Future Outlook: Technological Innovations in Swine Ultrasound

As precision livestock farming advances globally, ultrasound technology continues to evolve. Some promising developments include:

Automated Image Analysis

Artificial intelligence (AI)-driven software can automatically identify tissue boundaries and calculate fat thickness, reducing operator dependency and improving consistency.Cloud-Based Data Integration

Scanners increasingly offer wireless data transfer to farm management software, enabling real-time herd monitoring and benchmarking.Miniaturization and Wearable Sensors

Future developments may include wearable ultrasound patches for continuous monitoring of body composition in growing pigs.

These innovations promise even greater accuracy, efficiency, and accessibility for swine producers worldwide.

Conclusion

In modern swine production, precision matters. Ultrasound scanners have revolutionized how producers measure fat thickness, offering a non-invasive, real-time, and highly accurate window into body composition. Comparing different animal ultrasound scanners reveals that while high-end clinical machines offer superior resolution, modern portable devices like the BXL-V50 strike an excellent balance of accuracy, durability, and practicality for daily on-farm use.

As global swine industries face increasing pressure to optimize productivity, reduce environmental impact, and meet consumer demands for high-quality meat, ultrasound technology will continue playing a central role in achieving these goals. With ongoing advancements in software, AI integration, and training programs, animal ultrasound scanners are poised to become even more accessible and indispensable for pig farmers worldwide.

Reference Sources:

Zhang, W., et al. (2020). “Comparison of portable ultrasound systems for live swine body composition evaluation.” Journal of Animal Science and Biotechnology, 11: 25. https://jasbsci.biomedcentral.com/articles/10.1186/s40104-020-0437-y

Hansen, J.T., et al. (2022). “Precision feeding in Danish swine production: A case study.” Journal of Swine Health and Production, 30(4): 185-192. https://www.aasv.org/jshap/issues/v30n4.html

National Swine Improvement Federation (2023). “Ultrasound Scanning Guidelines.” https://nsif.com/Ultrasound

tags: